Are you planning a project that requires a durable and versatile material? Are you unsure which type of metal will best suit your needs? Suitable material is crucial for construction, manufacturing, or artistic purposes. One of the most popular choices in various industries is aluminium, known for its lightweight nature and excellent corrosion resistance.

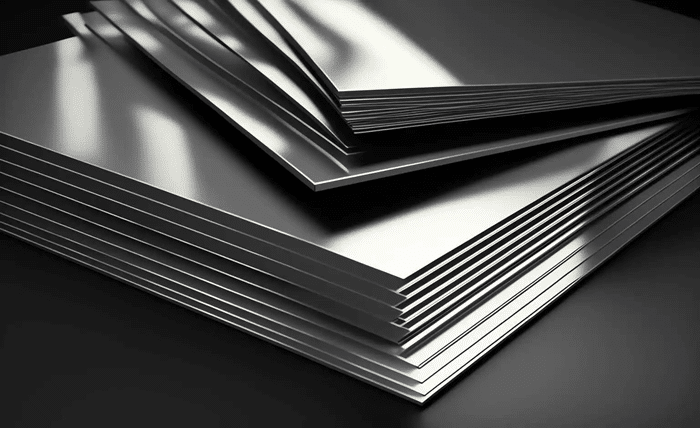

Understanding your project’s specific requirements is essential when choosing the most appropriate aluminium sheet. Different types of aluminium offer varying levels of strength, flexibility, and suitability for various applications. This page will explore the key elements to examine when selecting the most appropriate one for your project, ensuring you make an enlightened decision.

Understanding the Grades of Aluminum

The first step in selecting the correct sheet is understanding the different aluminium grades. They are categorised by a number system that indicates their composition and properties. For example, 1000 series sheets are nearly pure aluminium, offering excellent corrosion resistance and workability. On the other hand, the 6000 series are alloyed with magnesium and silicon, providing greater strength and versatility.

Consider the Thickness of the Sheet

The thickness plays an essential role in determining its suitability for various applications. Thicker sheets are typically more robust and can handle more significant structural loads, making them ideal for construction and heavy-duty applications. Thinner sheets, however, are more flexible and easier to work with, making them suitable for applications where precision and ease of handling are essential. Assessing the required thickness based on your demands is critical to ensuring optimal performance.

Evaluate the Finish and Coating

The finish and coating of the aluminium can significantly impact its performance and appearance. Some projects may require a polished finish for aesthetic purposes, while others might need a more rugged, coated surface to resist wear and tear. Anodised alum aluminium instance offers enhanced durability and corrosion resistance, making it perfect for outdoor applications. Consider your project’s environmental conditions and desired look when selecting the finish and coating.

Check for Specific Properties

Different sheets offer unique properties that can benefit your project. For instance, some sheets are heat-treatable, allowing them to be strengthened through specific processes. Others may have superior welding capabilities or be more resistant to certain chemicals. Identifying the properties essential to your project—such as tensile strength, flexibility, or thermal conductivity—will help you narrow your choices.

Determine the Intended Use

Another critical factor to consider is the intended use of the aluminium sheet. Structural applications require sheets with higher strength and durability, while decorative uses might prioritise aesthetic appeal and surface finish. By clearly defining the purpose of the sheet in your project, you can select a material that meets functional and visual requirements.

Consider Budget Constraints

Budget is always a consideration in any project, and aluminium comes in various prices depending on its grade, thickness, and finish. Higher-grade aluminium with specialised properties or finishes will typically cost more, but it may offer better long-term value if it more effectively meets your project’s needs. Balancing your budget with the required performance characteristics is essential to making a cost-effective choice.

Consult with a Professional

Talk with an expert can offer valuable insights if you’re unsure about choosing one. Experts in the field can offer recommendations based on their experience, helping you select the correct sheet for your project. They can also guide you on working with the material and any specific considerations that may arise during installation or fabrication.

Choosing the suitable aluminium sheet for your project involves carefully considering various factors. By understanding these elements and evaluating your specific needs, you can make an informed decision that ensures your project’s success. Whether dealing with a construction project, manufacturing process, or creative endeavour, selecting the suitable sheet will provide the aesthetic appeal required.